3D printing has become a much more mainstream technology, with printing machines available at just about every price point. Most people who want a 3D printer can probably find a model they can afford. Despite this, 3D printing is still so new that few people know how it works.

This is why now is a good time to answer the question “How does 3D printing work?”. There’s a very good chance you’ll have to use one eventually!

Additive vs Subtractive 3D Printing

There are two broad categories of 3D printing. The 3D printers that you can buy yourself are almost all “additive” machines. In other words, they build 3D objects by adding material (usually in layers) until the object is complete. The 3D printers people think of when they hear “3D printer” is almost always of the additive variety.

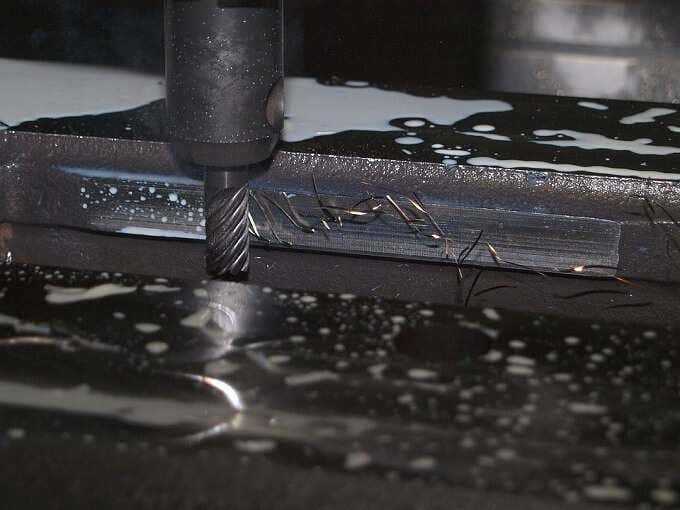

Subtractive 3D printing is very different. Here you start with a fixed amount of material and then remove material until only the finished object is left. A sculptor making a statue out of marble is using a subtractive method. Subtractive machines are usually found in large workshops and industrial settings. CNC milling (computer numerical control) systems are probably the best-known example.

We’ll only be concentrating on additive machines from here on out, since they’re relevant to the average consumer. Just know that subtractive machines belong to the same extended family of 3D printers as the one you might put on a desk.

Fused Deposition Modelling, Stereolithography and Selective Laser Sintering

The three main methods of additive 3D printing are FDM (fused deposition modelling), stereolithography (SLA) and selective laser sintering (SLS).

The da Vinci FDM Printer

FDM is the most common consumer-grade system. With these types of printers a filament of material is passed through a hot print head. The print head is precisely positioned in 3D-space and deposits a layer of material according to exact programmed instructions. There are different approaches to FDM, but we’ll get to that in a moment.

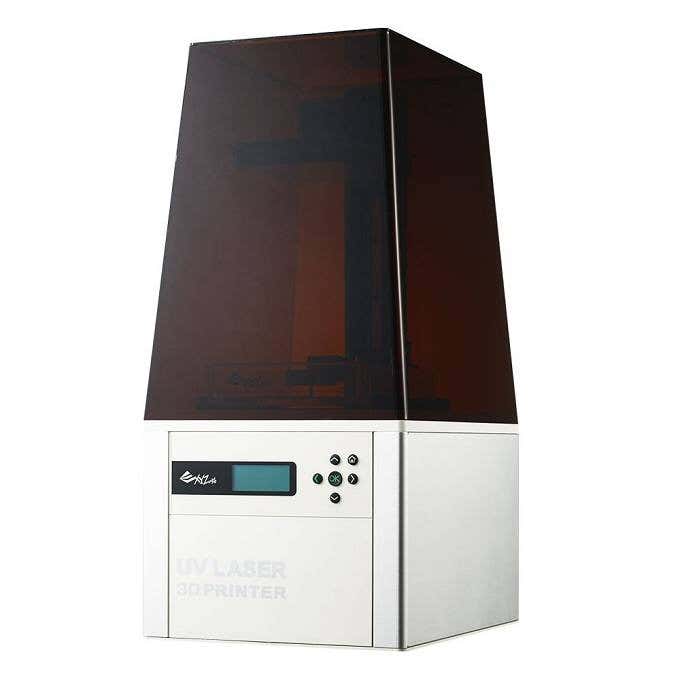

The Nobel SLA Printer

Stereolithography is much less common in consumer systems. These printers use lasers to cure a liquid resin into a solid plastic material. Usually, the object is “pulled” from a vat of resin, forming layer by layer as it rises from the material. In recent years SLA printers have become more compact and affordable. So it’s a real alternative to FDM printers, depending on what type of final model you settle on.

Selective laser sintering (SLS) uses a powerful laser to fuse a polymer powder. The actual powder acts as a support structure for the print, so this type of printing doesn’t need special scaffolding. SLS is not a type of FDM you’ll find on the desktop. It’s still an industrial technology for now.

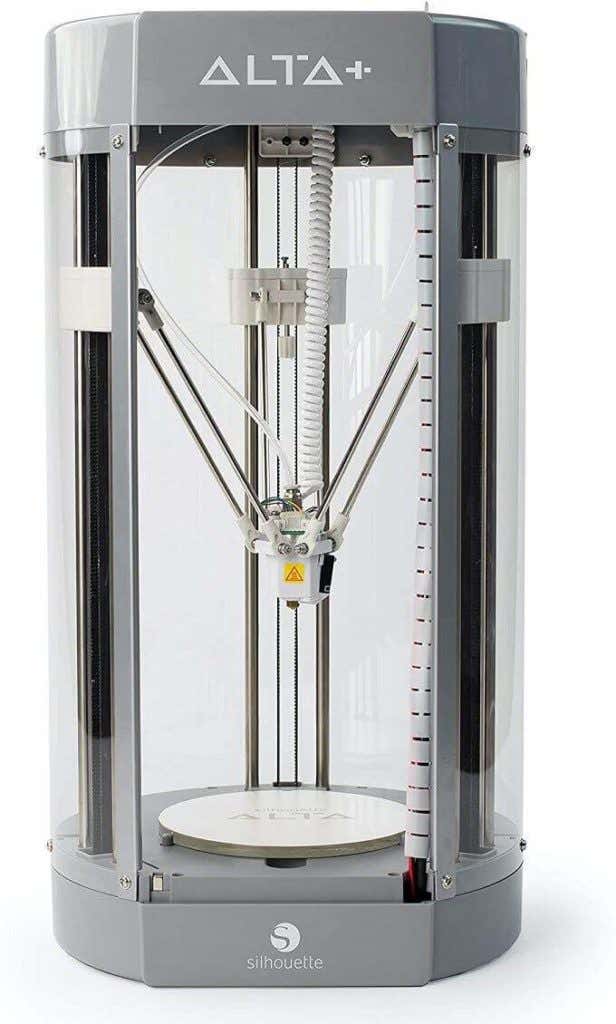

Cartesian & Delta Robot Printers

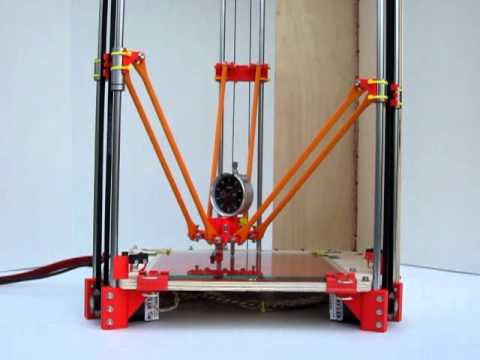

A Delta Robot Printer

The most common type of FDM printer is the cartesian 3D printer. The name refers to cartesian coordinates. That’s the XYZ coordinates we all learned in school. The print head can be moved to any XYZ coordinate within the print volume space. The math is simple, the printers are pretty affordable and print quality is precise.

However, depending on how granular the XYZ coordinates are, curved surfaces might not be as smooth as they could be, requiring some manual finishing work.

Delta robot printers take a different approach. The print head is mounted to three arms that run on three rails. By varying the height of each arm, the print head can swing. This design allows for the print head to swing in true curves and also allows for tall objects to be printed within the print volume.

Basically, the longer the rails are, the taller the model can be. Rather than XYZ coordinates, delta robot printers use trigonometry to calculate print head position. The end result is that they can’t reach quite the same print resolution as cartesian printers.

To really understand the delta robot concept, you need to see it in action. Have a look at this video by Johann Rocholl and you’ll quickly get the concept.

Notice the articulation on the arms and how freely and smoothly the print head can move.

3D Printer Materials

3D printers use a variety of materials, but there are two plastics that are by far the most common in consumer-grade applications: ABS and PLA.

ABS (Acrylonitrile Butadiene Styrene) is exactly the same plastic that LEGO bricks are made of. This plastic is susceptible to warping when cooling down and needs a printer with a heated print bed. It’s quite impact resistant, but not particularly strong. It’s suitable for making prototype parts and even final parts that aren’t load-bearing.

PLA (Polylactic Acid) has a low melting point, doesn’t warp much, is easy to work with and has fewer failed prints. It’s also far too brittle for any practical use, but it is brilliant for creating smooth, detailed models that are only meant to be looked at.

The good news is that most consumer 3D printers will work with both of these inexpensive materials. So you can change them out as your needs require.

Nylon filament is another option and there are even printers that use wood or metal as a material. Next-generation printers can also handle more than one filament at a time, allowing for mixed material or multi-color prints.

The Typical 3D Printing Process

If you’ve never made a 3D print yourself, you’re probably curious about how it actually works from a user perspective. While using a 3D printer isn’t as easy as knocking out 2D prints on a laser or inkjet printer, it’s not nearly as difficult as you might think.

After setting up the printer according to the manual, with calibration and levelling done correctly, you first need a model to print.

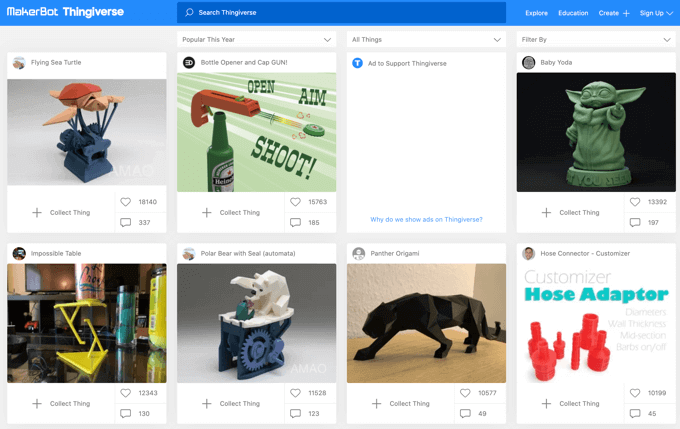

You can make your own model, using something like Zbrush or AutoCAD, but most people are likely to download a model from an online site. The first stop should definitely be Thingiverse, which is quite possibly the most famous collection of user-submitted models. However, there are many alternatives.

After getting a model in a compatible format, you’ll open it up in the software that came with your printer. They all look and work differently, but the basic concept is the same. You may also want to first treat a 3D model with Meshmixer, which ensures that a 3D model is solid and suitable for printing.

In the 3D printer software, you’ll pick the size and quality of the model and the software will convert it into “slices” representing each print layer. It will also calculate the “scaffolding” that has to be printed to support the model while it’s being made. This stuff can be broken off when the print is done.

With all that prep work behind you, the print can begin. Depending on the quality settings, you might be in for a long wait! High quality prints vary from a few hours to a few days. Thankfully, some 3D printers let you monitor the progress of your print remotely via an app.

Once the print is done, you’ll remove it from the bed and then break it free of the scaffolding. In many cases you’ll have to finish the model using sandpaper and special cutting tools to remove imperfections. Some people even paint their models! The only real limit is your creativity.

If you’re itching to buy a 3D printer, these are our best picks and if you’re on a budget, these are more pocket friendly options.