In yet another stop along our journey to find the best affordable entry-level 3D printers, we had a chance to try out the Kobra 3D printer from Anycubic. The Kobra is a minimal-assembly kit that costs US $299.00 on Anycubic’s official website and on Ali Express. Or you can buy it on Amazon for $319.99.

In this 3D printer review, we’ll let you know what you get when you buy an Anycubic Kobra, what it’s like to build it, and our first impressions about its quality and usability.

Features of the Kobra by Anycubic

The Kobra by Anycubic is an FDM 3D printer. FDM stands for fused deposition modeling. The print material for FDM printers is plastic filament. If you’re considering buying your first 3D printer, you could also consider a resin printer like the Anycubic Photon Mono X, the larger Photon Mono X 6K, or the Photon M3.

The Kobra’s features include:

- Build volume of 9.8 x 8.7 x 8.7 in. (250 x 220 x 220 mm)

- Machine dimensions of 19.1 x 19.1 x 16.9 in. (486 x 486 x 430 mm)

- Uses 1.75mm PLA, ABS / PETG & TPU filaments

- Ø 0.4 mm replaceable nozzle

- A heated, textured, removable, and flexible build platform made of PEI spring steel

- Ports for USB and microSD card

- 4.3″ color touchscreen LCD

- 25-point auto bed leveling with an inductive sensor using Anycubic’s LeviQ technology

The Kobra has a direct-drive extruder, which is relatively uncommon among printers at this price point. In general, filament printers have either a direct-drive extruder or a bowden extruder. Bowden extruders push the filament into the nozzle from a distance, guided through a teflon tube, whereas direct drive extruders are mounted right above the hot end, greatly reducing the slack inside the tube because it’s so much closer to the nozzle.

The Kobra has an inductive probing sensor for automatic bed leveling. It’s a proximity sensor that can detect nearby metals. It’s not quite as accurate as something like the BL Touch but it’s dramatically cheaper and can give you excellent results. Prusa uses these on printers that are twice as expensive, like the Prusa MK3.

The heated bed has a spring steel sheet that attaches to a magnetic top on the bed, making it incredibly easy to remove your prints. Just remove the spring steel sheet and crack it like an ice tray. In our test print, the print even released itself from the bed as it cooled. Moreover, the bed leaves a nice texture on the underside of the print.

The LCD touchscreen is quite similar to the screens on some of Anycubic’s other printers, like the Anycubic Vyper. It’s intuitive, responsive, and easy to read.

The print volume is quite similar to the Vyper’s, as well, and the print beds are identical. Lastly, the Kobra has optional filament run-out detection. You can turn that feature on or off via the touchscreen panel.

Assembling the Anycubic Kobra 3D Printer

The Kobra comes partially assembled—another reason it’s a good option for beginners to 3D printing. You’ll learn how the printer’s mechanics work as you assemble it, and it won’t take very long since many of the parts are already put together for you.

It took us about fifteen minutes to assemble the Kobra. The instructions were fairly clear, although the photos in the assembly manual could have been larger. There’s not a whole lot to mess up. The cable management is where you want to be the most careful.

The stepper motors are already mounted. They just needed to be plugged in using the provided wiring.

Calibration

Anycubic recommends checking the tension of the belts and ensuring the build plate and x-axis don’t wobble. We didn’t need to make any adjustments to the eccentric nuts which control how tightly the rollers grip on the aluminum extrusions. You don’t want them too tight, and you definitely don’t want them too loose. If you do need to adjust them, it’s fairly simple. You just turn the eccentric nut until the wobbling stops—and no tighter.

If you do need to adjust the belt tension, it’s straightforward. There’s a screw tensioner for each belt. A couple turns of those screws, and you’re done.

After performing the automatic bed-leveling, we calibrated the z offset. To do that, you put a piece of paper under the nozzle and adjust the offset until it ever-so-slightly grips the paper. You’ll need to fine-tune this as the first layer is being printed. We had to raise the z offset 0.1mm. Your results will vary.

Build Quality of the Anycubic Kobra

The only thing we didn’t like about the build quality is that the z-axis only has one lead screw. Despite that, the x-axis seemed pretty stable. We didn’t notice any sagging.

The cooling fan is a bit noisy, but we probably wouldn’t have noticed if the printer weren’t so quiet.

The filament spool is positioned at the top of the printer. We would have preferred it at the bottom since any extra weight at the top of the direct-drive extruder could make the printer shake. On the other hand, there was no evidence of that happening during our prints.

First Print

For our first test print, we used the test file included on the SD card and printed with Anycubic PLA filament. We didn’t try printing with ABS filament because, in our experience, that requires an enclosure to have any hope of getting the quality you expect from PLA.

We had no problems with bed adhesion on our first print. The print partially released when the bed cooled, which was nice.

As you can see, we got a good print on our first attempt. There was minimal stringing (really, almost none at all). The only large defect was caused by a piece of plastic we failed to remove from the nozzle. We were particularly impressed by the print quality of the ears at the top of the owl—printers often struggle with thin parts that are at a steep angle and are separated, requiring the nozzle to lift and move.

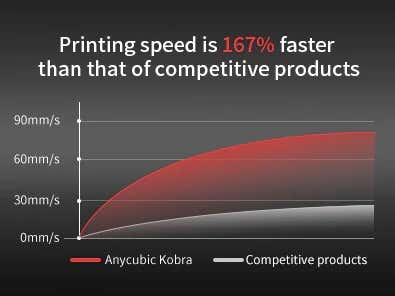

Anycubic says the Kobra’s printing speed is 167% faster than competitors. While the print speed isn’t the fastest we’ve ever seen, we expected that. It’s a trade-off for having a direct-drive extruder instead of a bowden. In our opinion, the responsiveness of a direct-drive extruder is an acceptable tradeoff for the slightly slower print speeds.

Cut to the Chase

Virtually every entry-level 3D printer gets compared to the Ender 3. In this case, the Kobra out-performs the Ender 3 in these areas:

- Less stringing because of the direct-drive extruder

- Comes with a magnetic bed for easy print removal

- No x-axis sagging

- Vastly superior touchscreen

With the Kobra, you’ll get high-quality prints for under $300. If you’re interested in a similar printer with a much larger build volume, keep an eye out for our upcoming review of the Anycubic Kobra Max, a monster FDM 3D printer we simply loved.

*Special thanks to FormerLurker for help in reviewing Anycubic’s Kobra 3D printer.

Related Posts

Maggie Marystone is a freelance technology writer, human rights worker, and storyteller based in Chicago. Read Maggie’s Full Bio